Maize Thresher Machine

Engineered for Indian farms of all sizes, Maize Threshers deliver fast, reliable, and efficient maize processing. With power options from 0.75 kW to 1.5 kW, cutting speeds from 1600 to 2000 RPM, and output capacities reaching 2000+ KG/HR, these machines offer stable performance, low electricity consumption, and long operational life across small, medium, and large-scale field requirements.

Designed for maximum grain recovery with minimal effort, Maize Threshers combine powerful motors, stable RPM balance, and low energy consumption to deliver smooth, clean, and high-output threshing — ideal for boosting productivity on any farm size.

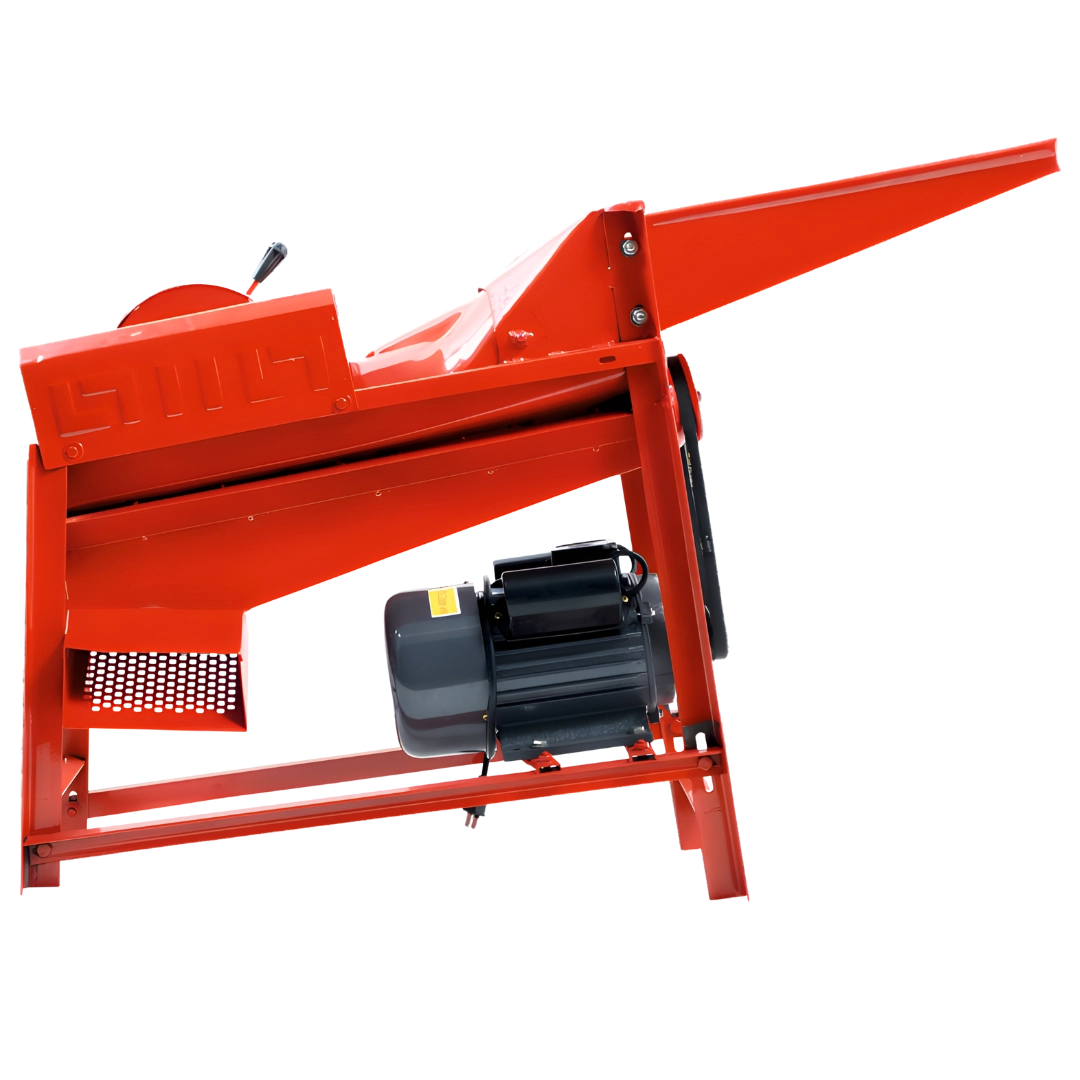

2.0 HP Maize Thresher | 2000+ kg/hr Output | 2800 RPM Motor | Royal Kissan

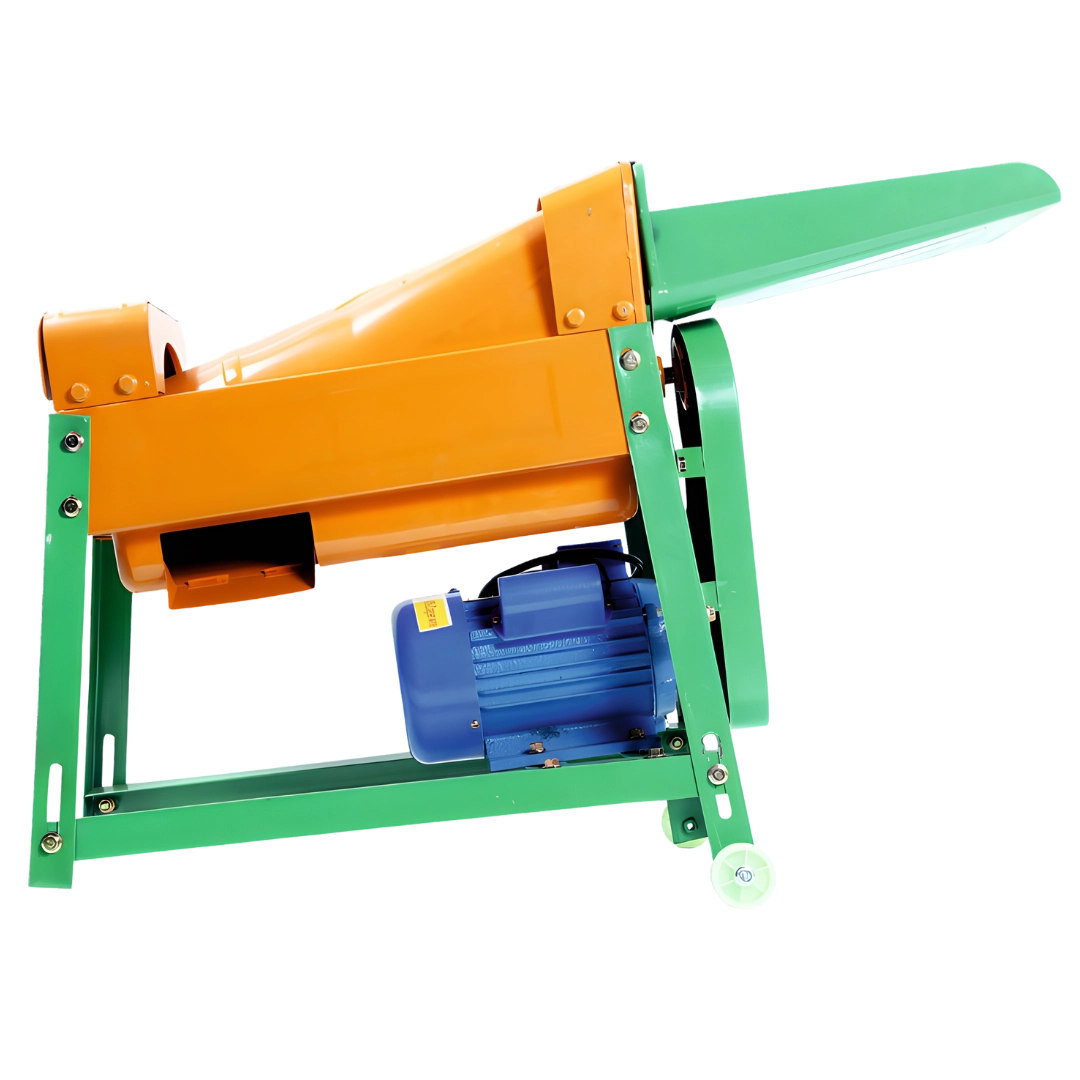

1.0 HP Maize Thresher | 1500 kg/hr Output | 2000 RPM Cutting Speed | Royal Kissan

Semi-Automatic 1.0 HP Maize Thresher | 1500-2000 kg/hr Output | Maize Thresher 3 | Royal Kissan

Designed to deliver real value by mechanizing key tasks and boosting productivity

Farmer From

This brush cutter from Royal Kissan Agro is strong and easy to operate. It cleared thick weeds in my field quickly, making farm work much easier

Farmer From

Royal Kissan Agro’s water pump in Tamil Nadu delivers water strongly and reliably. It keeps our irrigation running even in dry spells and has boosted our rice yield

Farmer From

In Telangana I rely on this chaff cutter for my cattle fodder. It shreds stalks finely and quickly, saving hours of work and helping my cows eat better

Farmer From

The chainsaw from Royal Kissan Agro is strong and easy to handle. In Andhra we use it to cut firewood and clear branches; it works quickly with no issues

Farmer From

Royal Kissan Agro’s hose pipe is flexible and durable. In Karnataka, it's essential for irrigating my tea plantation, delivering water evenly without any leaks

Farmer From

This sprayer from Royal Kissan Agro sprays evenly and is easy to carry. In Kerala’s paddy fields, it helped me apply fertilizer quickly and improved my harvest

Everything you need to know about our products and services

A maize thresher is a farm machine that separates corn kernels from the cob quickly and efficiently. Instead of manual shelling, which is slow and labor-intensive, a thresher processes large quantities of maize, cleaning the grain and leaving minimal waste. Royal Kissan threshers are designed to handle both maize and similar grains with high efficiency.

The price of a maize thresher depends on its capacity and features. Royal Kissan offers a range from compact models for small farms to high-capacity machines for large-scale operations. We recommend checking the specific model pages or using the “Enquire Now” button for the most accurate and up-to-date pricing, as well as current availability and offers.

Royal Kissan offers a complete range of electric maize threshers to suit every farm size:

Selecting the right model depends on your typical harvest volume:

You can explore the full range of Royal Kissan maize threshers right here on our official website. Royal Kissan is a leading agriculture machinery manufacturer in India. This means you are buying directly from the source—ensuring genuine OEM quality, better after-sales support, and direct access to spare parts. We also have a network of dealers across India; use our “Become A Dealer” or “Contact” page to find one near you.

WhatsApp us