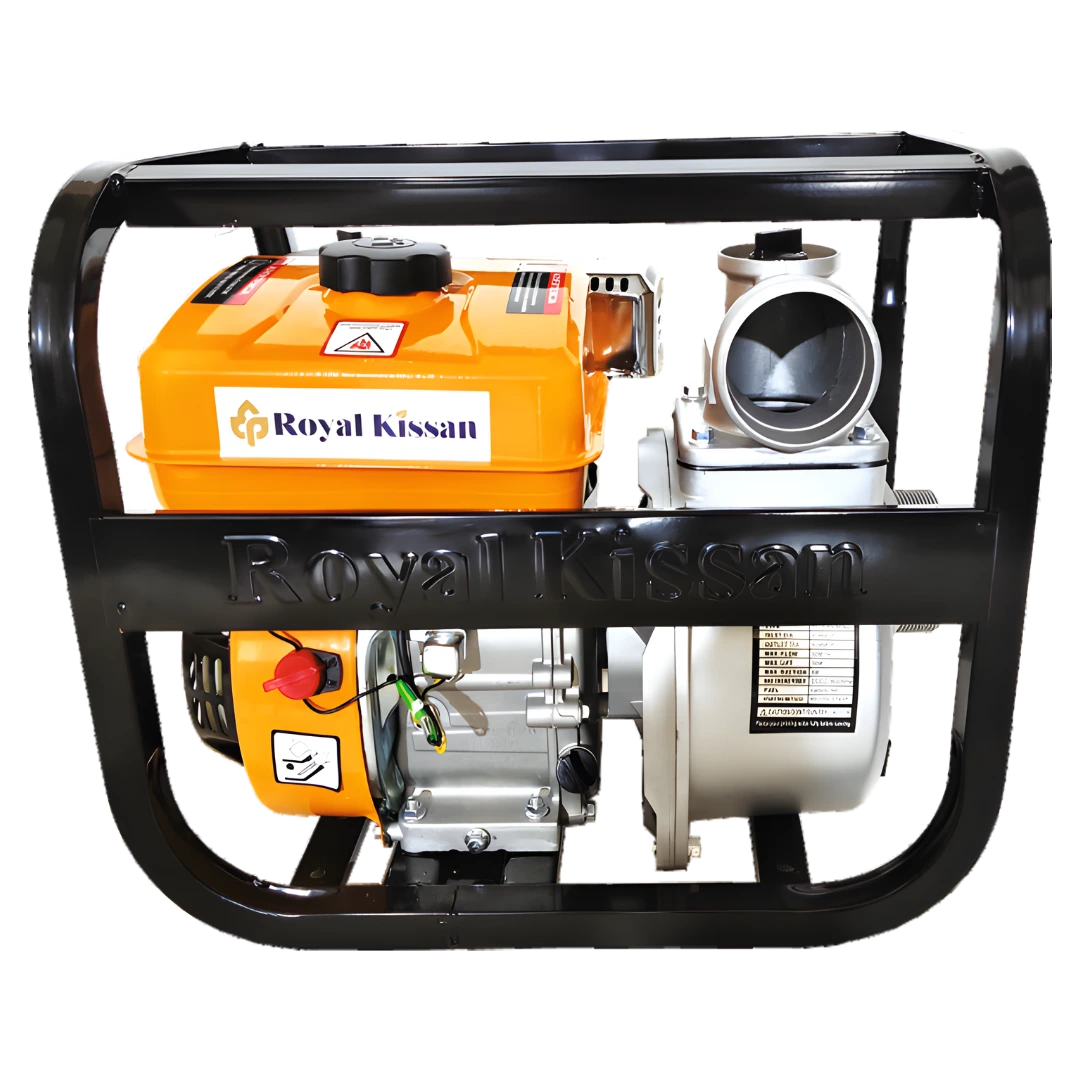

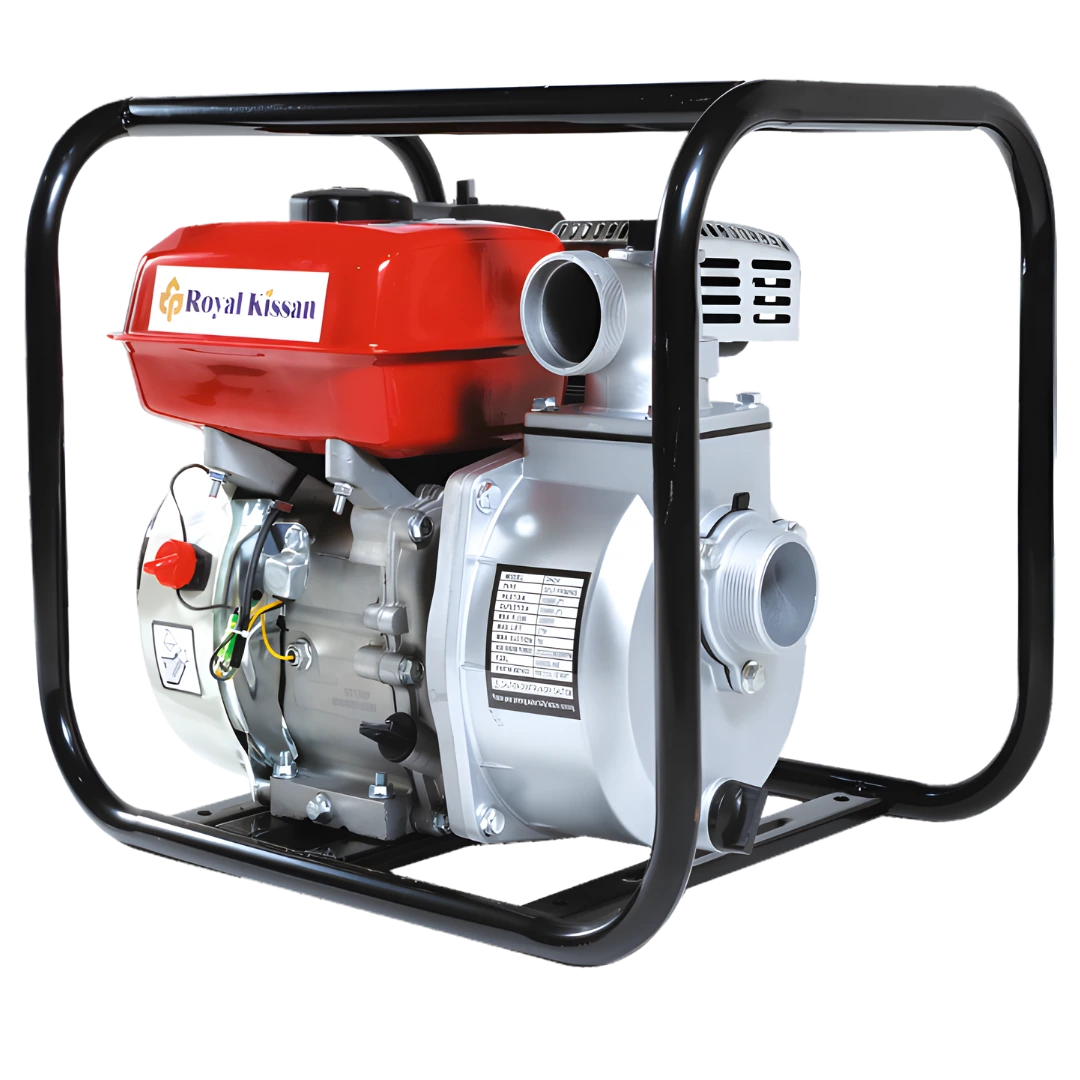

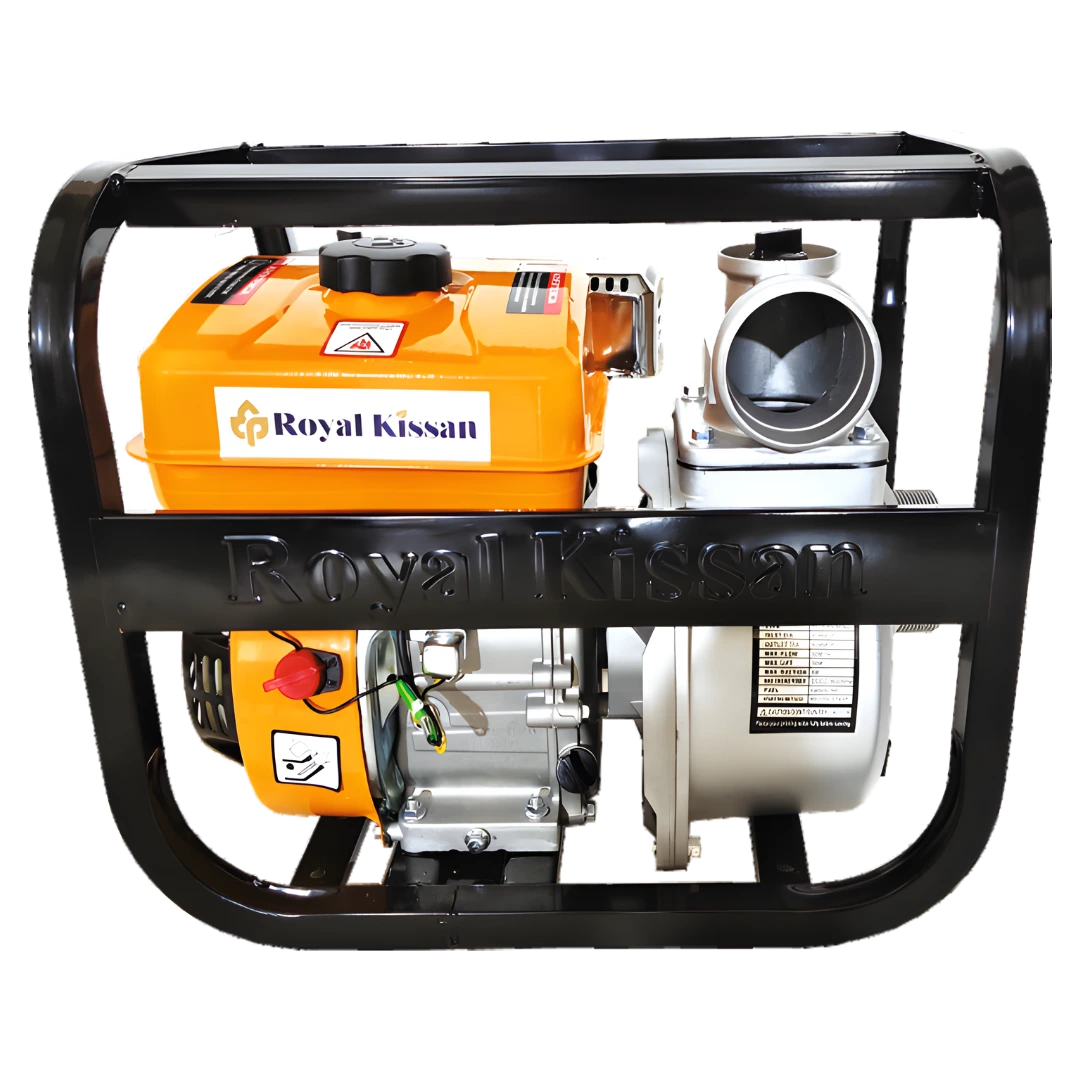

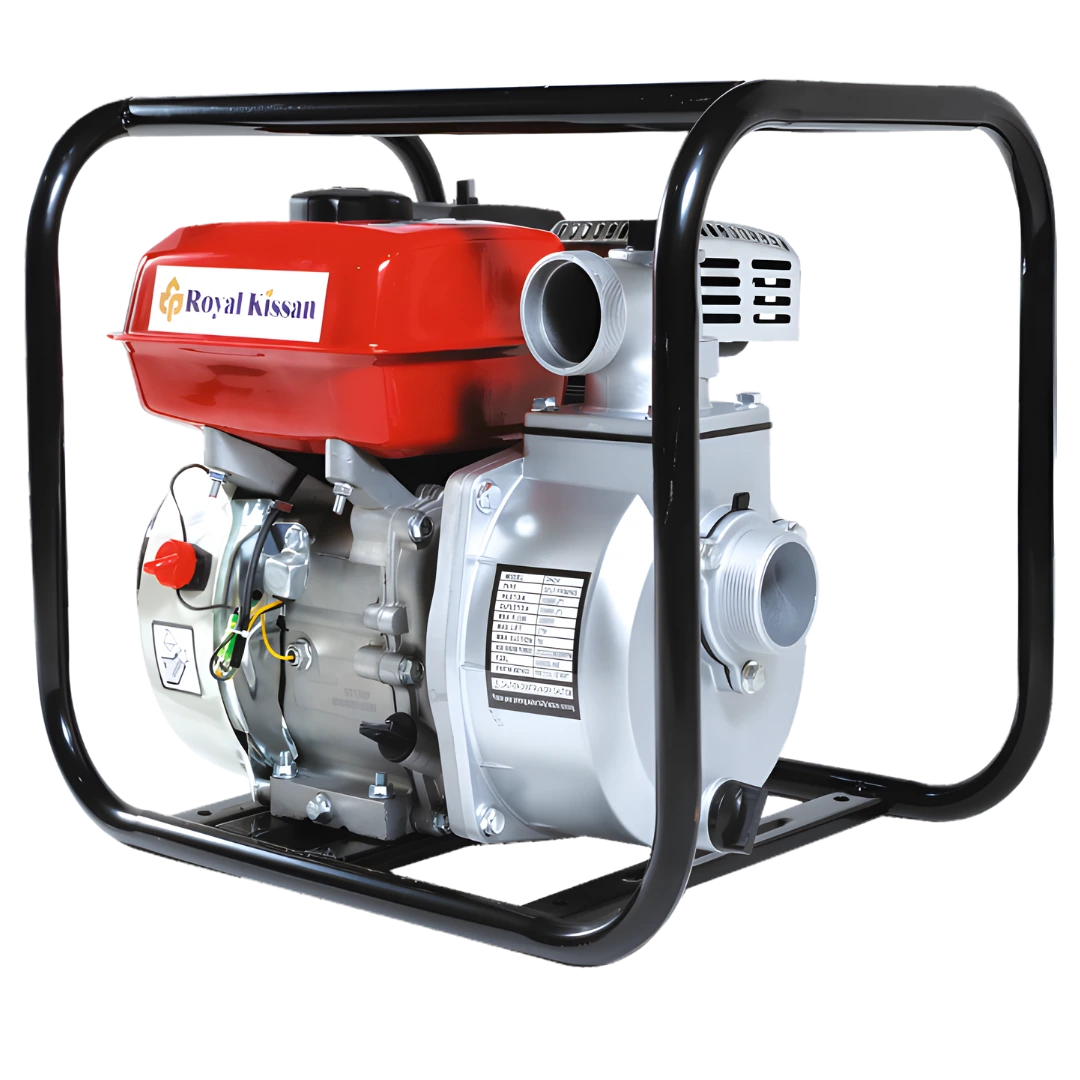

Built with robust 4-stroke engines and corrosion-resistant parts, they deliver strong suction (up to ~30m) and wide discharge for fast, reliable water flow across large fields—all with minimal effort and downtime.

Delivers strong lift, steady flow, and fuel-efficient performance for quick, uniform irrigation on any farm.

Ultra Premium 5.1HP Water Pump | RK-WP-UP3 | 212CC | 4-Stroke | Royal Kissan

Premium 5.1HP 4-Stroke Water Pump | RK-WP-P03 | 212CC Petrol Engine

Premium 5.1HP 4-Stroke Water Pump | RK-WP-P02 | 212cc Engine

Premium 2.5HP 4-Stroke Compact Water Pump | RK-WP-P1.5 | 98cc Engine | Royal Kissan

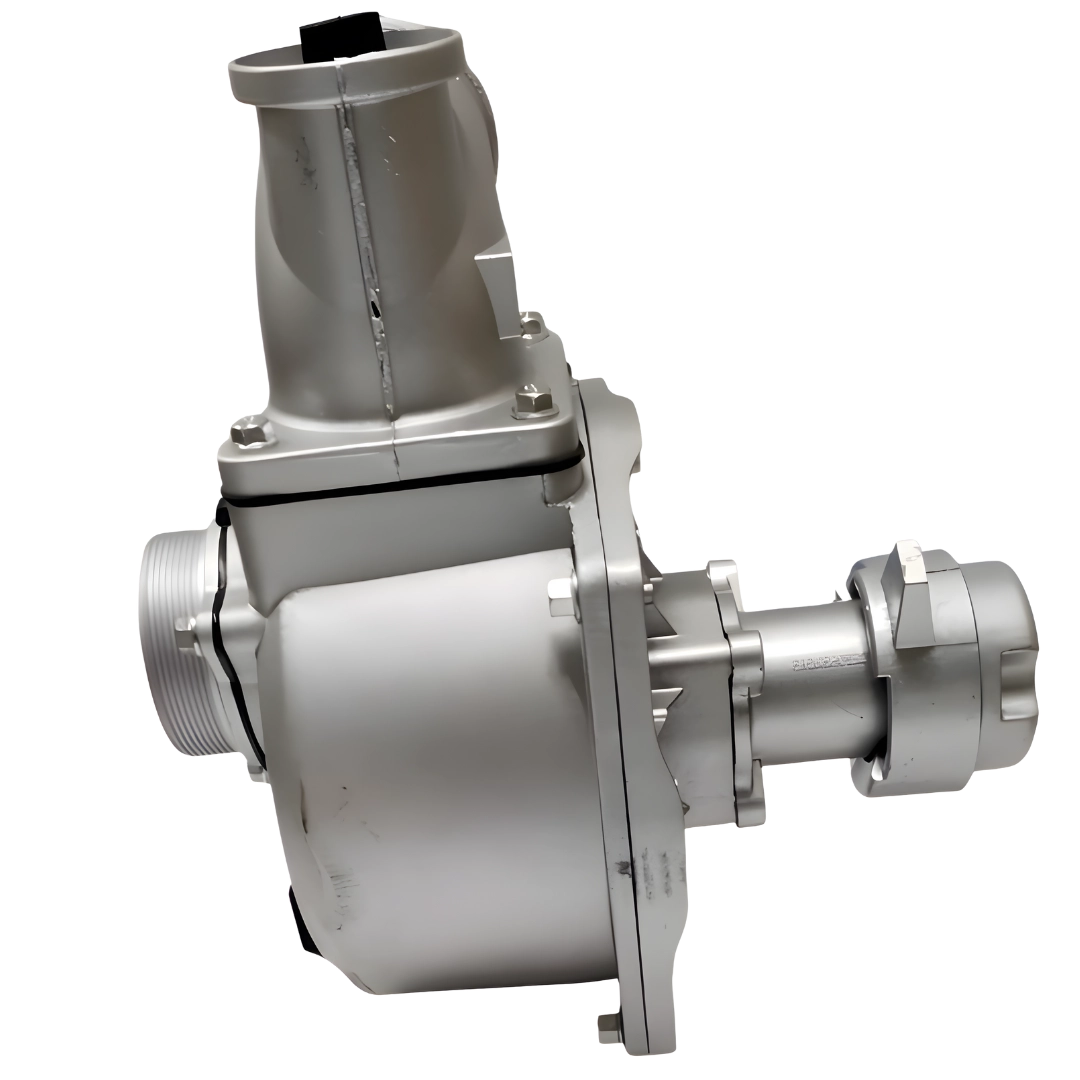

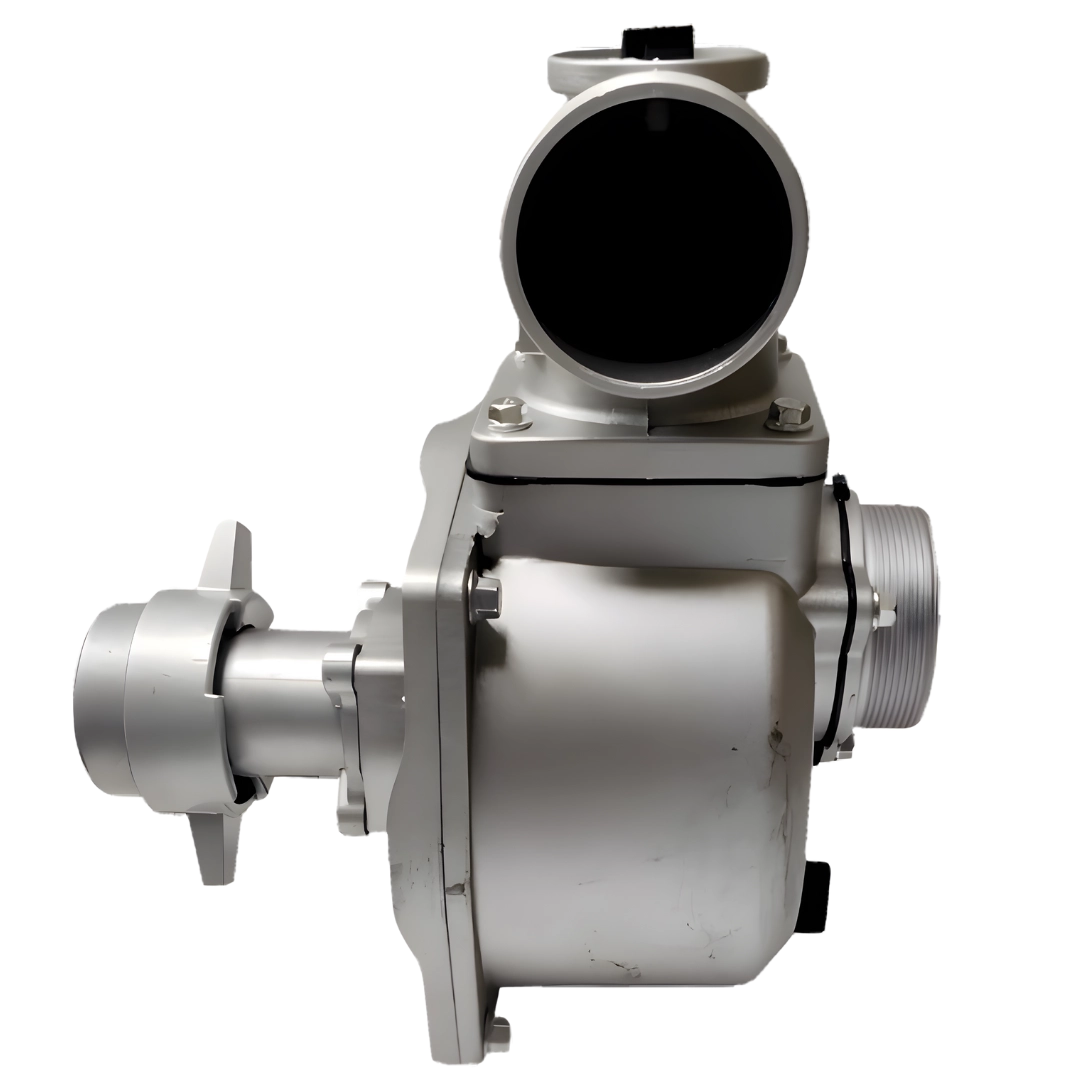

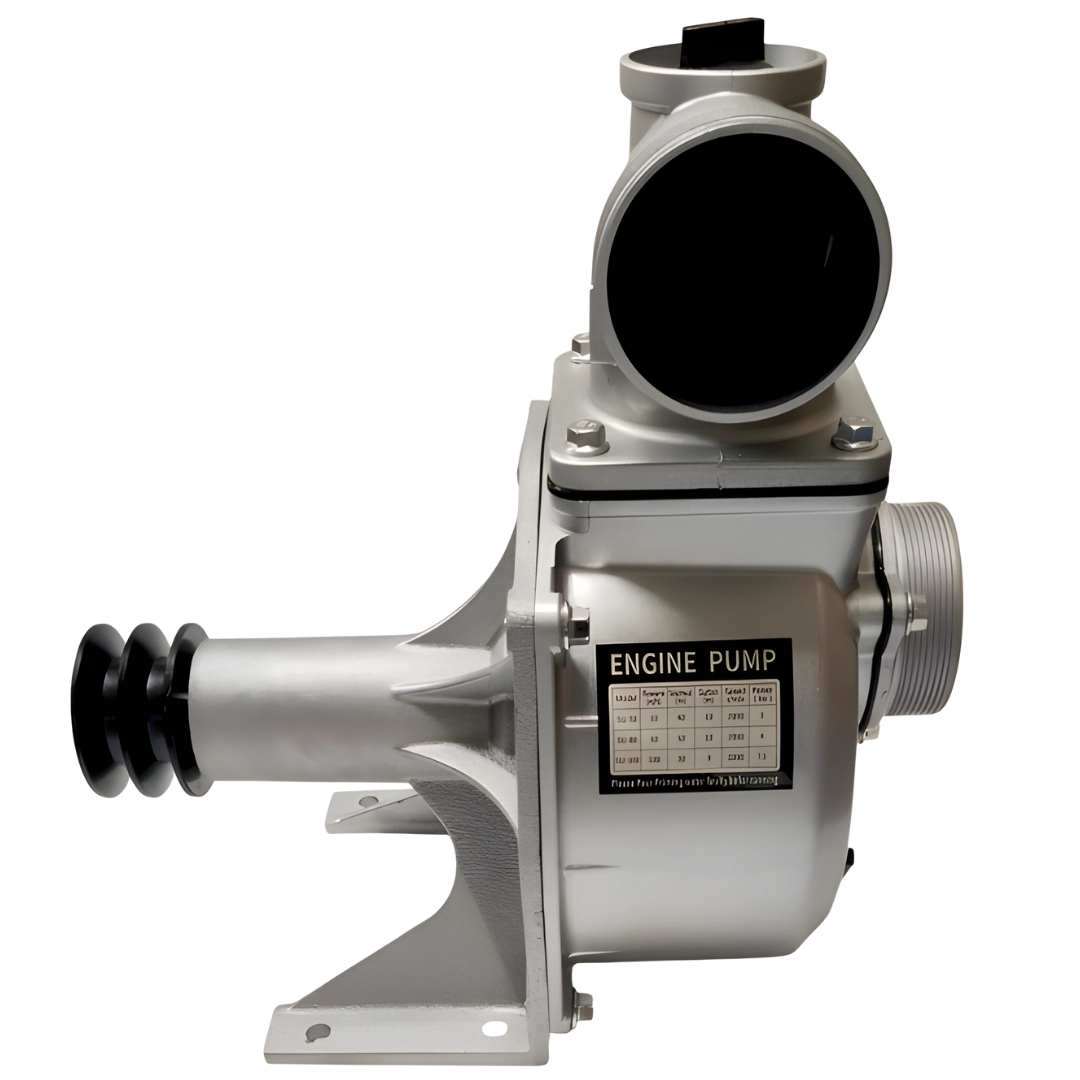

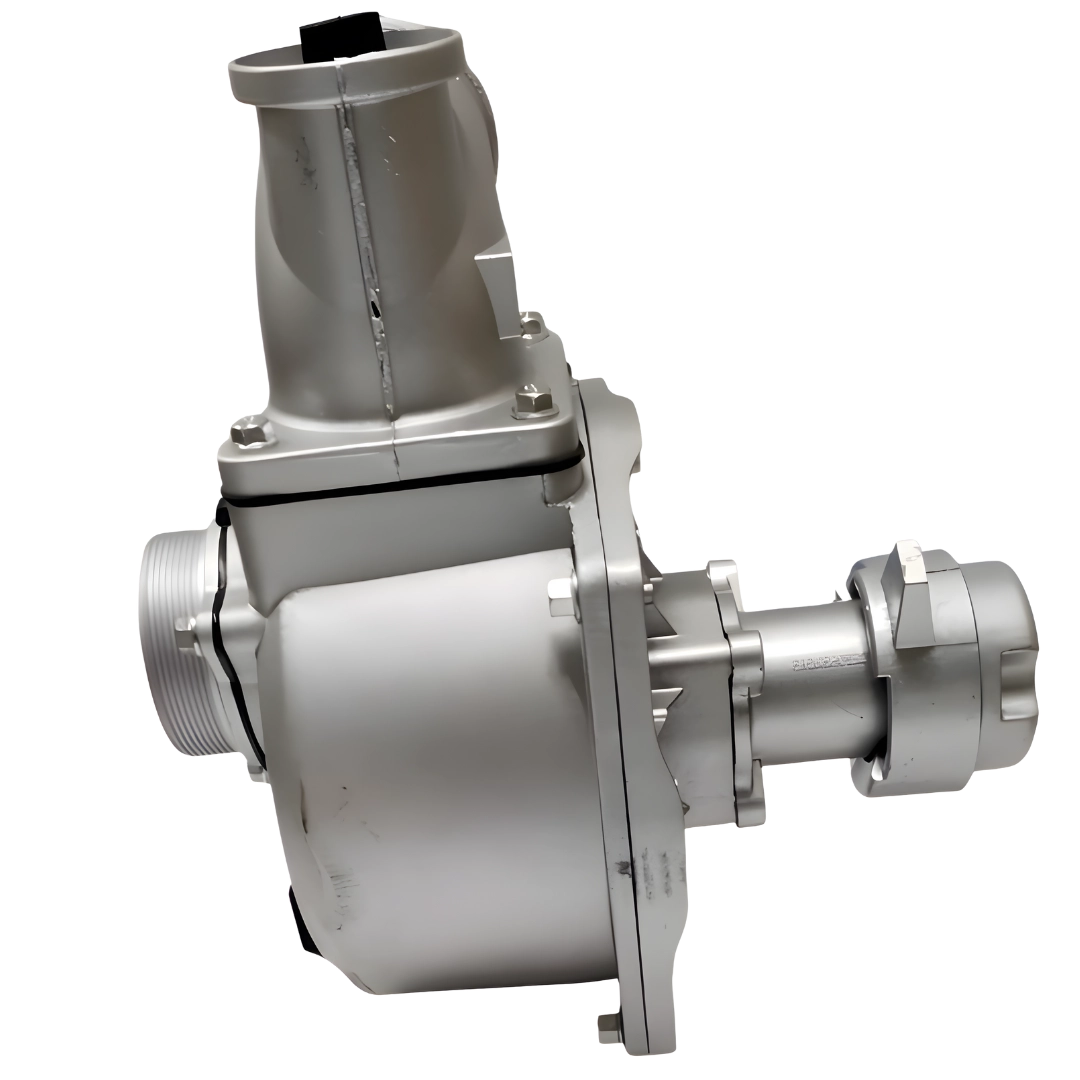

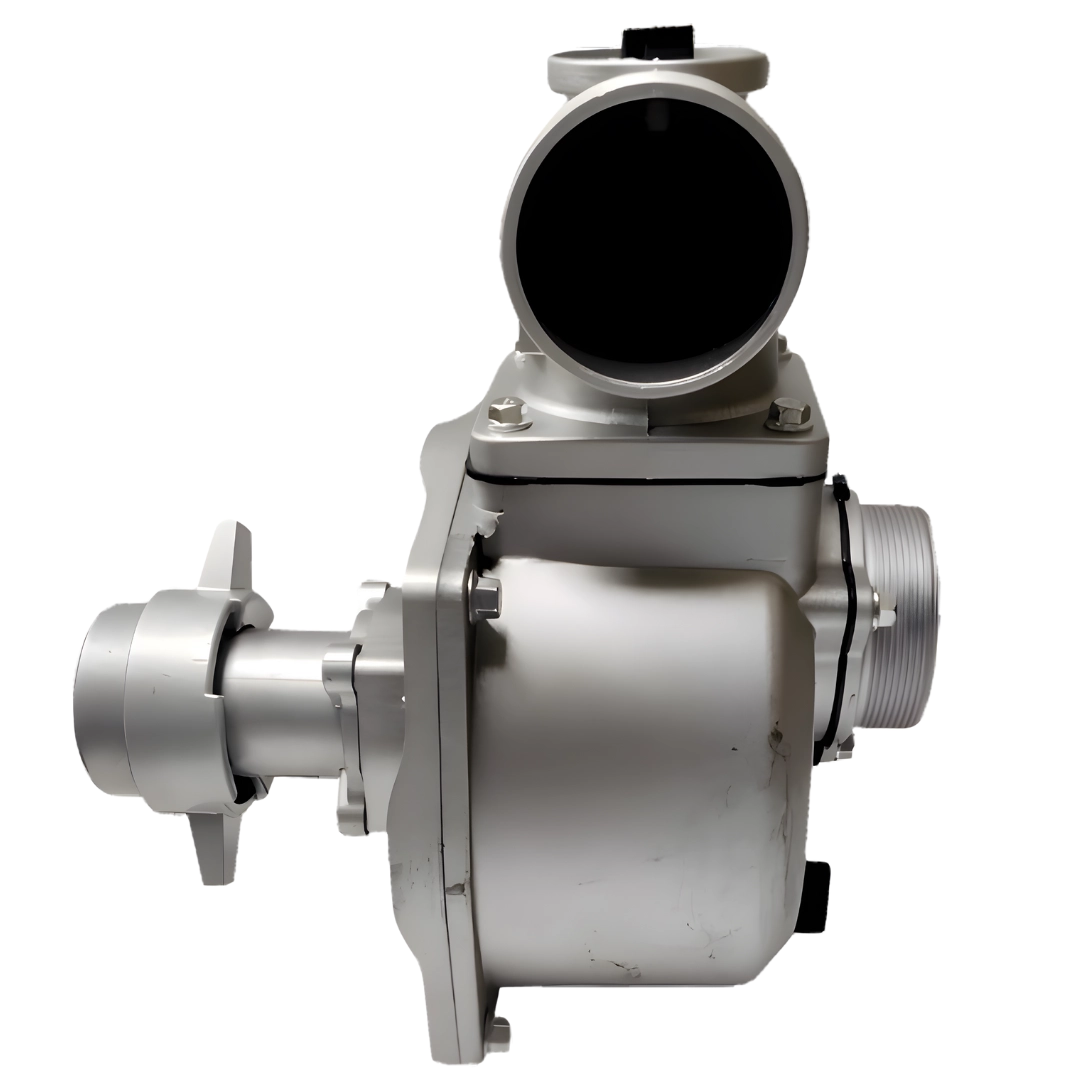

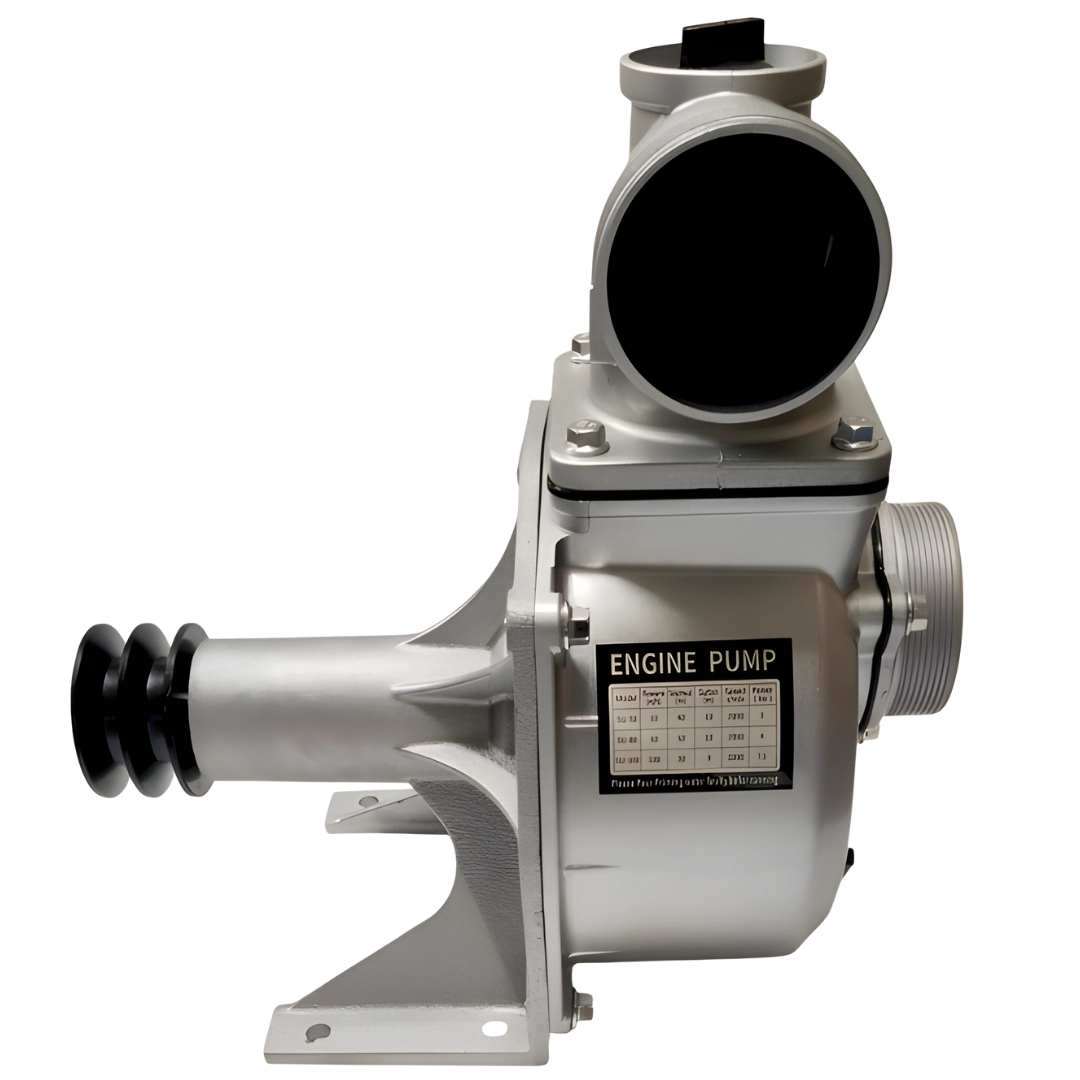

Uses PTO or belt drive to power durable pumps for heavy-duty irrigation, firefighting, and wash-downs.

Water Pump Attachment | Gear Drive Diesel Models | RK-PW-WP-D80 | 3 INCH / 80MM

Best Water Pump Attachment | Agricultural Equipment | RK-PW-WP-P80 | 3 INCH / 80MM

Belt Drive Water Pump Attachment | RK-SU80 | 3 INCH / 80MM

Submerged electric pump moves sludge or wastewater efficiently with quiet cooling, high lift, and clog-free output.

Royal Kissan Submersible Sewage Water Pump | 1HP High-Flow Model | WQD10-11-0.75A

Royal Kissan WQD15-10-1.1FA | Submersible Sewage Pump 1.5HP | 15M Head

Royal Kissan 1.5KW Sewage Pump | WQD15-15-1.5FA | 19M Head, 416L

Designed to deliver real value by mechanizing key tasks and boosting productivity

Farmer From

This pump easily lifts water from canal outlets for our sugarcane and banana fields. Its strong suction and high flow cover acres fast. The engine starts on first pull and runs smoothly all day. We use less fuel and finish irrigation in half the time.

Farmer From

In our large paddy and wheat fields, the pump delivers uniform water pressure across every section. Even after hours of continuous use, it stays cool and reliable. No clogging or loss of power. We’ve seen irrigation efficiency improve and water usage decrease.

Farmer From

Perfect for our banana and horticulture farms, the pump’s high lift reaches distant canal levels easily. It maintains steady flow in humid, hot weather without overheating. The lightweight design means our operators handle it all day without fatigue. It’s built tough for long hours.

Farmer From

We use this pump for irrigating cotton and chili plots. It handles uneven terrain with strong, consistent pressure. Even with long runs, the engine stays cool and fuel consumption is low. The pump’s sturdy build has required no repairs so far, despite heavy use.

Farmer From

Our paddy fields and mango orchards benefit from the pump’s high head and flow – it reaches the farthest field corners. The engine is easy to start and runs with low vibration. We save on fuel and time, and its reliability means we never worry during the peak season.

Farmer From

In the humid monsoon months, this pump performs flawlessly in rubber and vegetable gardens. Its corrosion-resistant parts resist rust in wet conditions. It maintains strong discharge even on hilly slopes. Quick to assemble and operate, it drains or fills reservoirs efficiently.

Everything you need to know about our products and services

Royal Kissan, a leading agricultural machinery manufacturer in India, offers three main types: portable water pumps (like the RK-WP series) with self-contained petrol engines for general irrigation; water pump attachments for power tillers and tractors, which use PTO or belt drive for high-flow, heavy-duty irrigation; and submersible sewage water pumps (WQD series) designed to handle sludge and wastewater efficiently. This range covers everything from a mini water pump for small plots to high-capacity pumps for large farms.

A standard water pump (portable or attachment) is designed to move clean water from a source (like a pond or river) to your fields for irrigation. A water pressure pump is typically used to boost water pressure in a line, often for sprinkler systems. A submersible sewage pump is a specialized electric pump placed directly in wastewater to pump out sewage, sludge, and drainage water. It’s built with clog-resistant mechanisms to handle solids. Royal Kissan offers specific models for each distinct application.

Yes, absolutely. A water pump attachment for a power tiller is a highly efficient solution. Instead of having a separate engine, it connects to your power tiller’s PTO or belt drive. This setup provides higher power and flow rates, making it ideal for irrigating large fields quickly. It’s a cost-effective way to utilize your existing power tiller for heavy-duty irrigation, firefighting, or wash-downs without needing an additional dedicated pump engine

As an agricultural machinery supplier in India, Royal Kissan offers competitive pricing on all pumps. The exact price of a sewage pump varies based on its power (HP), head capacity, and flow rate. To choose the right pump for sewage water, consider the total head (vertical lift + friction loss) and the volume of water you need to move. Our submersible models, like the WQD15-15-1.5FA, are designed for efficient, clog-free output. For the best price and model recommendation, please contact our team with your specific requirements.

For clean irrigation water, our portable and attachment pumps are ideal. However, for dirty water, sewage, or sludge, you must use a purpose-built submersible sewage pump. Royal Kissan’s WQD series pumps are specifically engineered for this. They are designed to handle solids, resist corrosion, and prevent clogging, ensuring reliable performance in demanding wastewater applications.

WhatsApp us